Baked with Love

A Valentine’s Recipe for Concrete

Move over, chocolate cake. There’s a new mix in town!

Every love story starts in the kitchen, not with grand gestures, but with preparation.

Measuring, mixing, and paying attention to the details that matter.

At Anthony Concrete Design, working with concrete has always felt like baking, and during Valentine’s season, it feels a lot like telling a love story. One built on patience, chemistry, and showing up for the process, even when it takes time.

Every piece we make is a carefully mixed composition, designed with intent, poured with precision, and finished with care. From hearths and wall panels to kitchen islands and statement mantels, our work is shaped slowly and thoughtfully, never rushed. Like any good relationship, it’s built step by step.

This is our recipe, not for something sweet, but for something lasting. Architectural-grade concrete, baked with love.

Yields: One High-Performance

Concrete Form

Prep Time: Deep Design Sessions + Collaborative Conversations

Mix Time: ~40 minutes

Cure Time: 24-48 Hours

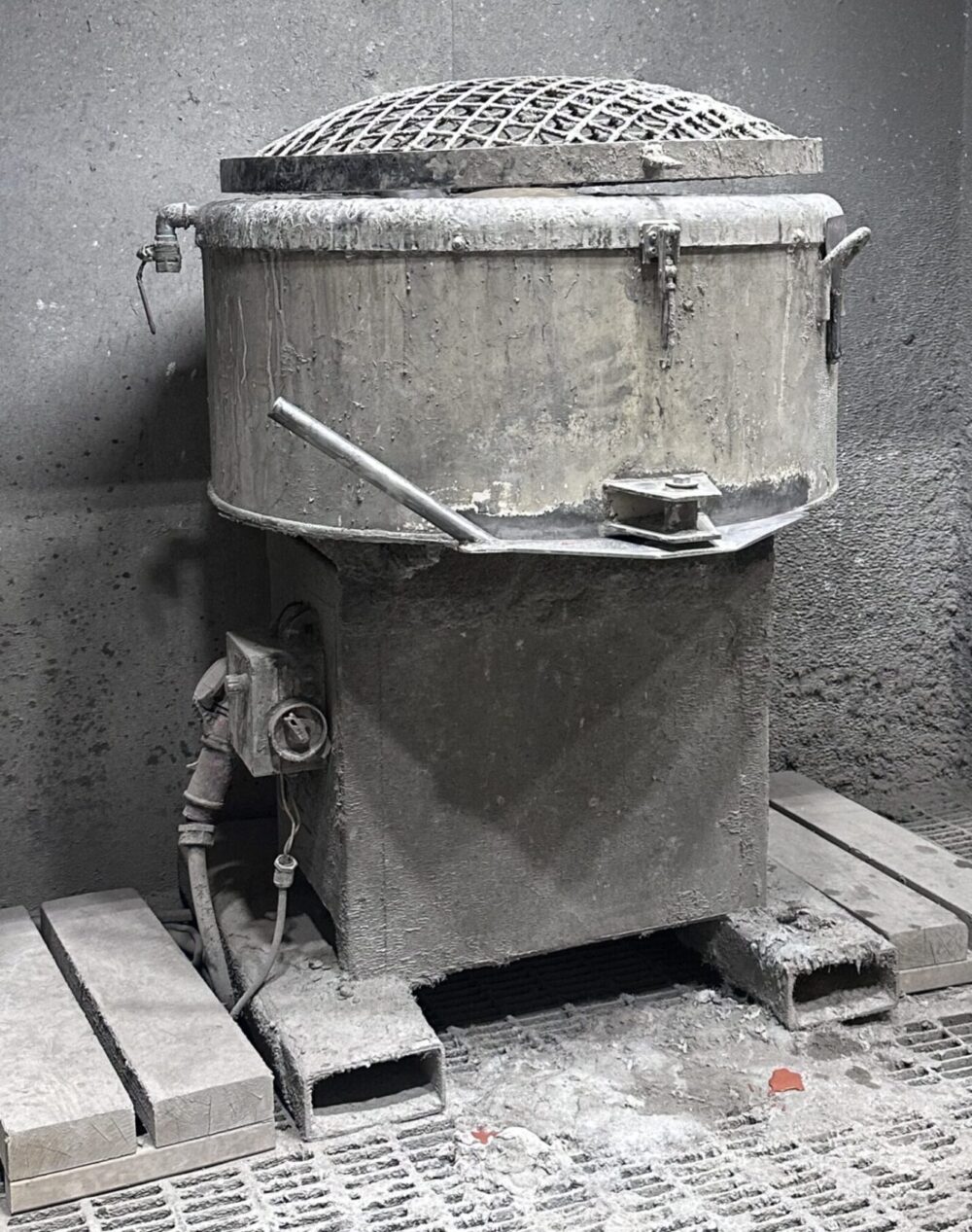

Tools of the (Concrete) Kitchen

Every love story has its constants. Ours look a lot like this.

Design Software – Our digital prep station, where forms take shape before concrete hits the mould!

Concrete Mixer – Essential for preparing consistent, blended batches.

Custom Moulds – Designed to capture edges, curves, and architectural intent.

Concrete Vibrator – Like tapping the cake tin, but for airless perfection.

Finishing Tools – Grinders, polishers, and sealers.

We don’t just use equipment; we rely on it like chefs trust a favourite knife.

Every tool in our shop exists for one reason: to bring the material to its most beautiful, functional form.

Method:

1.The First Meeting

Before anything is mixed, there’s preparation.

Layouts, 3D visuals, colour and texture review and mix tests come first, not as a checklist, but as a conversation.

This is where we listen, ask questions, and begin to understand the project and the people behind it.

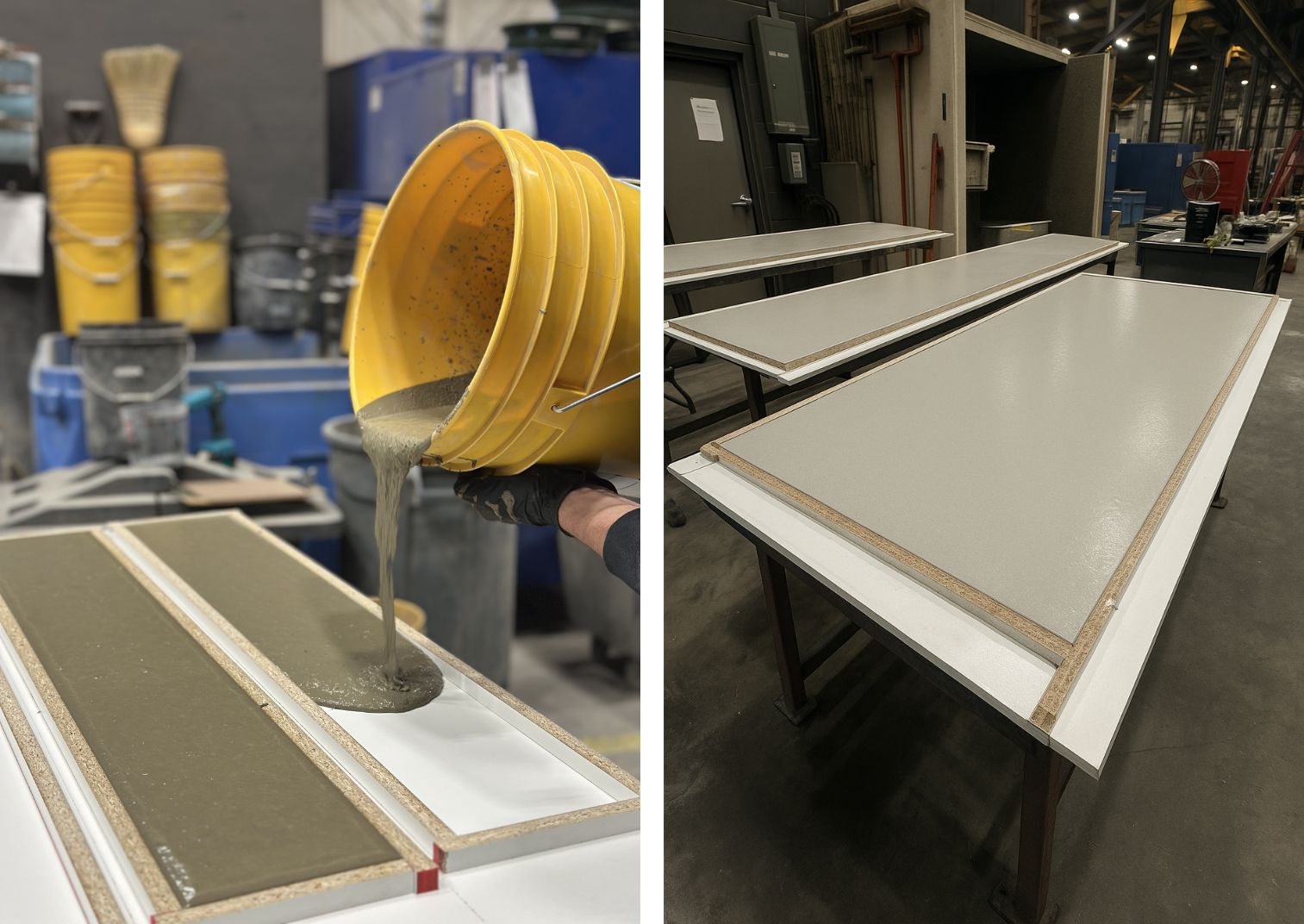

2. Chemistry

Then comes the mixing. Ratios matter, but so does feel. If the mixture is too dry, it becomes difficult to pour and increases the number of bug holes. If it is too wet, it loses strength.

This is where chemistry reveals itself, adjusted carefully, tested patiently, and refined until the balance feels right. Like any good relationship, it’s built on knowing when to add and when to hold back.

3. Commitment

The pour is done carefully and the team works quickly to avoid dry lines. The mix flows into the mould while it vibrates to release trapped air and prevent imperfections. This is the point where planning turns into action, where preparation gives way to commitment, and the piece begins to form.

4. Trust

Just like dough needs time to proof or custard requires time to set, concrete also demands patience. Unlike anything in the kitchen, concrete has its own unique process: it generates heat as it cures.

This slow, internal reaction occurs out of sight but is essential for the strength of the final product.

5. The Reveal

De-moulding is careful and deliberate, sometimes requiring a hammer, a drill, or even a crane. Once free, we wash, let it dry and seal. It’s in these final moments, handled with care, that the true character of the work is revealed.

A Valentine’s Season Ending

As Valentine’s season arrives, it feels like the right moment to slow down and appreciate the things we value most, the ones that aren’t rushed but shaped over time with care, patience, and intention until they quietly become part of everyday life.

That’s how we think about concrete, not as a moment or a gesture, but as something meant to stay, something made to be lived with and to grow more meaningful over time.